Nikka Densok

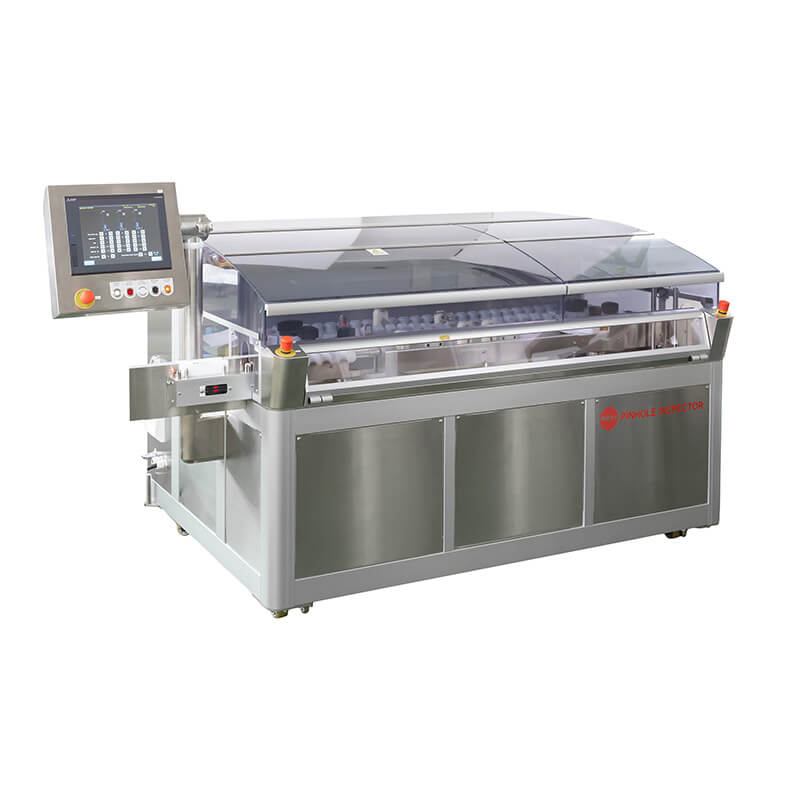

Japan-based Nikka Densok is one of the pioneering manufacturers of inspection equipment utilizing alternating current technology for leak detection in the pharmaceutical industry.

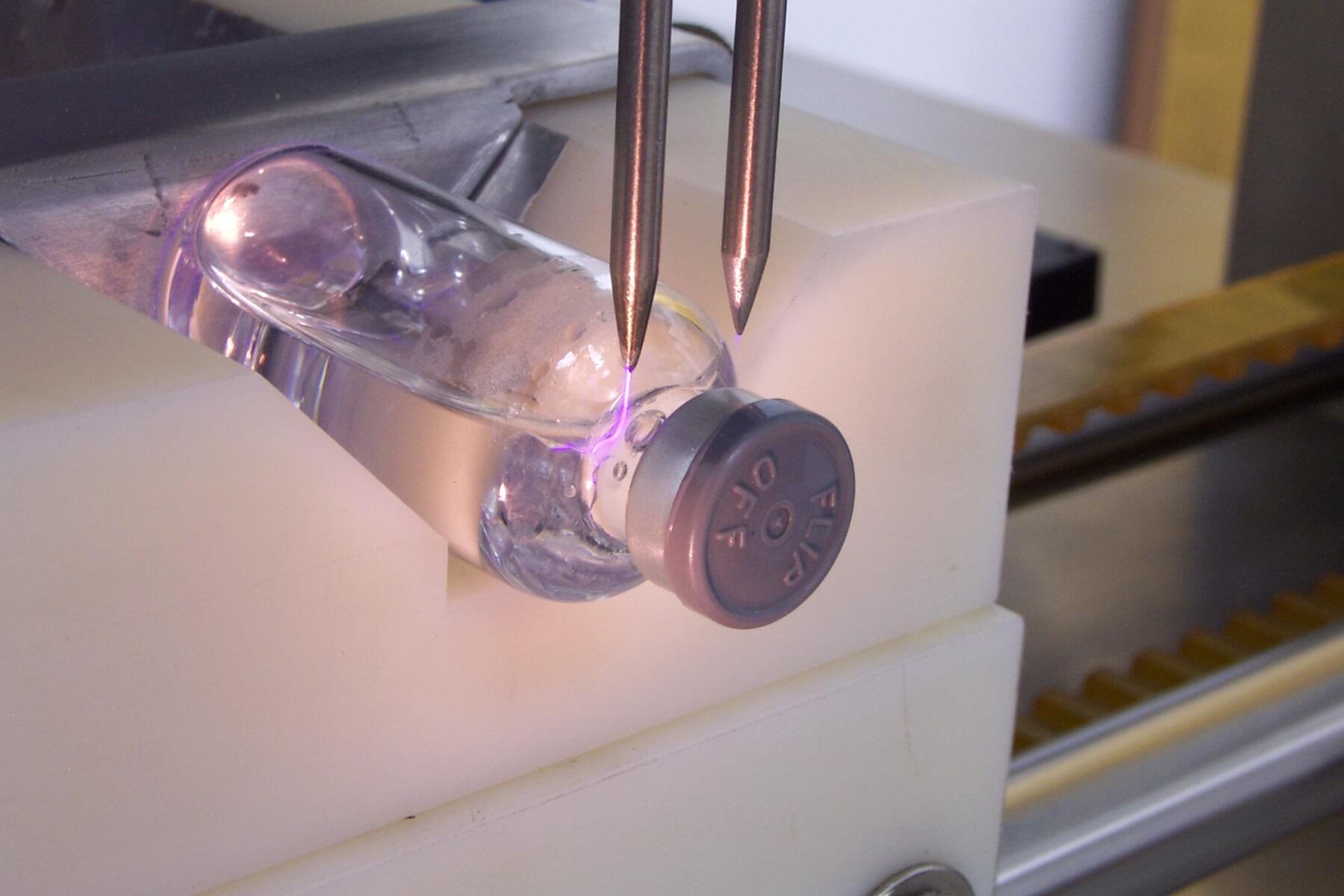

The company’s Pinhole Inspectors enable non-destructive testing of a wide variety of pharmaceutical and food packages, including glass, plastic, and flexible containers filled with conductive solutions. Using the High Voltage Leak Detection (HVLD) method, the system reliably detects micro pinholes, microcracks, and closure defects that are not visible through traditional visual inspection, ensuring product integrity.

Capable of detecting defects as small as 5 microns, the system eliminates the risk of secondary contamination and provides 100% non-destructive inspection. Nikka Densok’s innovative approach offers ideal solutions for production environments where the highest precision and process safety are required.

- Detectability of ≥5 micron size holes

- Detectability of cracks

- 100% Non-Destructive

- Eliminates the risk of secondary contamination in the product

- 100% inspection possible

Nikka Densok Equipment group

- BFS Vial Card – 120 vial cards/min

- BFS/large bottles – 6,000 bottles/hour - 100mL-1000mL

- BFS/small bottles – 2mL – 100mL

- Glass vial/ampoule - 400 vials/min - 2mL – 100mL vial - 1mL – 30mL ampoule

- IV bag & flexible packaging high-speed - 80 bags/min - 50ml – 1000ml

- IV bag medium speed – 6,000 bottles/h – 100mL-1000mL

- PFS – 80+syringes/h - 1ml, 2ml, 5ml

- Benchtop unit for glass vial & BFS

- Pinhole inspection for glass vial & BFS - 1mL to 100mL

- IV bag & flexible packaging lab scale

- PFS lab scale - 1mL – 5mL