Nikka Densok

Japonya merkezli Nikka Densok, ilaç endüstrisinde alternatif akım teknolojisini sızıntı kontrolü alanında kullanan öncü denetim ekipmanlarının üreticilerinden biridir.

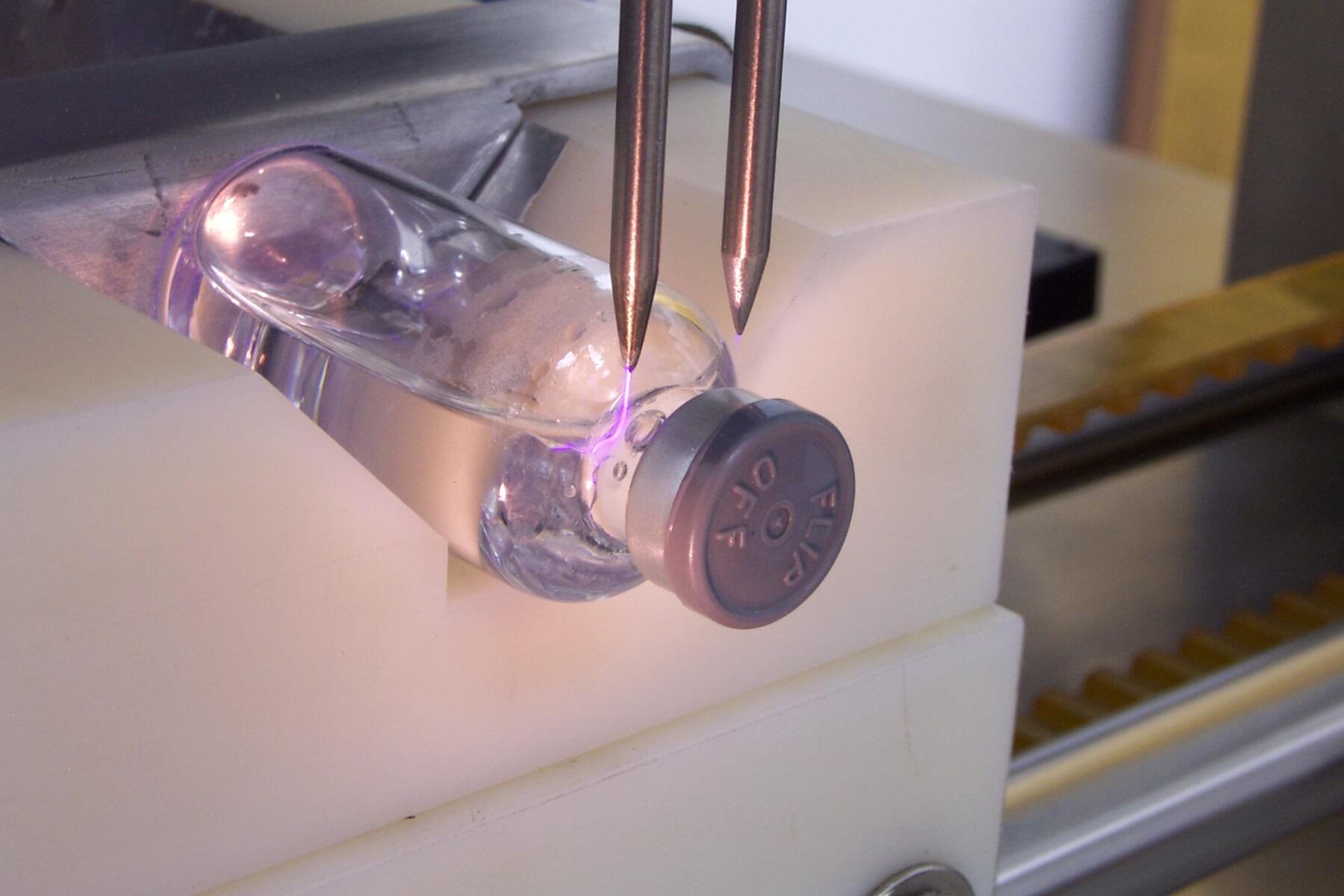

Firmanın geliştirdiği Sızıntı Denetim Sistemleri (Pinhole Inspectors), iletken çözelti içeren cam, plastik ve esnek ambalajlar dahil olmak üzere çok çeşitli farmasötik ve gıda ambalajlarının tahribatsız testini mümkün kılar. Yüksek voltajlı sızıntı testi yöntemi (HVLD), görsel denetimle tespit edilmesi mümkün olmayan mikro iğne deliklerini, mikro çatlakları ve kapama hatalarını güvenilir bir şekilde algılayarak, ürün bütünlüğünü garanti altına alır.

Sistem, 5 mikron çapındaki en küçük kusurları dahi algılayabilir; böylece ürünün ikincil kontaminasyon riskini ortadan kaldırır ve %100 tahribatsız kontrol imkânı sunar. Nikka Densok’un bu alandaki yenilikçi yaklaşımı, yüksek hassasiyet ve süreç güvenliği gerektiren üretim ortamları için ideal çözümler sağlamaktadır.

- ≥5 mikron boyutlu deliklerin algılanabilirliği

- Çatlakların algılanabilirliği

- %100 Tahribatsız

- Üründe ikincil kontaminasyon riskini ortadan kaldırır

- %100 muayene mümkün

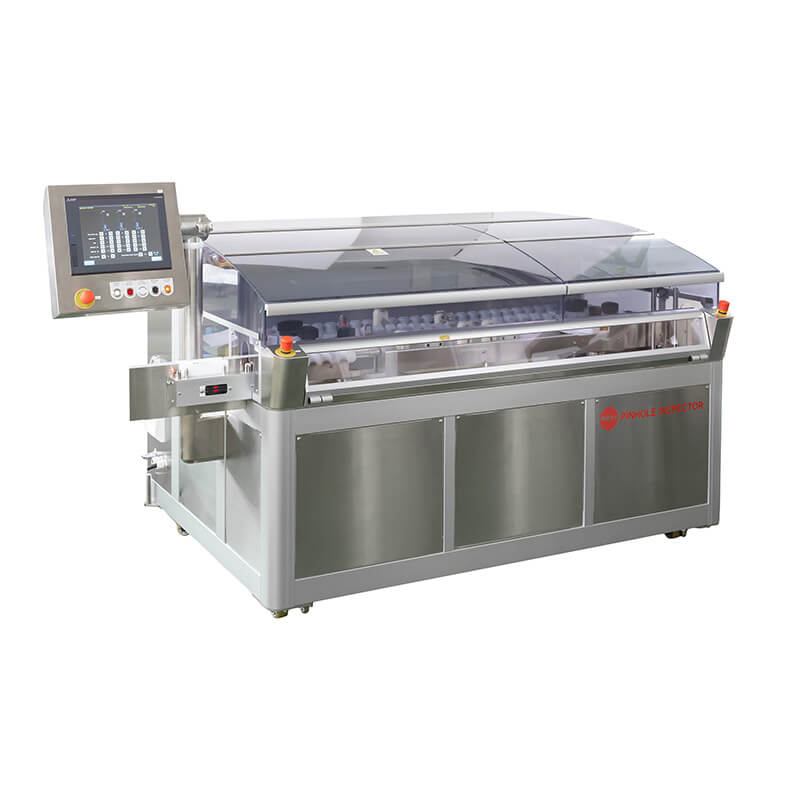

Nikka Densok Ekipman grubu

- BFS Vial Card – 120 vial card/dk

- BFS/büyük şişe – 6,000 şişe/saat - 100mL-1000mL

- BFS/küçük şişe – 2mL – 100mL

- Cam vial/ampul - 400 vial/dk - 2mL – 100mL vial - 1mL – 30mL ampul

- IV bag & esnek ambalaj yüksek hız - 80 bag/dk - 50ml – 1000ml

- IV bag orta hız – 6,000 şişe/saat - 100mL-1000mL

- PFS – 80+şırınga/saat - 1ml, 2ml, 5ml

- Cam vial & BFS için masaüstü ünite

- Cam vial & BFS için iğne deliği denetimi - 1mL to 100 mL

- IV bag & esnek ambalaj laboratuvar ölçekli

- PFS laboratuvar ölçekli - 1mL – 5mL