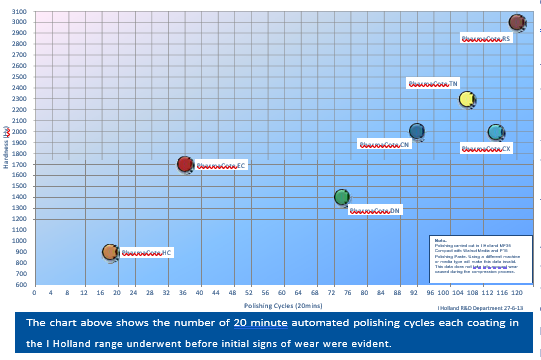

Punch polishing is a critical part of any tool care regime and, if carried out correctly, good polishing can help to prolong the life of tablet compression tooling.Automated polishing forms Step 5 of the 7 Step PharmaCare® SOP for punch and die maintenance. So what are the benefits of automated polishing over manual polishing?

Automated polishing offers clear advantages in terms of operational performance as well as economic benefits. Firstly automated polishing eliminates any potential variation that the manual process can bring, as punches can be polished to a micro fine, consistent finish allowing smoother operation in the tablet press. Manual polishing is essentially a destructive process where over polishing and the subsequent removal of material is quite commonplace. Additionally, it is very difficult to achieve a consistent finish across a tool set with a manual polishing process. With automated polishing, a consistent finish is achieved across a batch of punches within a mere 20 minute cycle, freeing up manpower within the tool room to focus on other tasks.

Modern tooling is often supplied with coatings, automated polishing is essential to ensure these coatings are not removed prematurely. Automated polishing ensures optimum and consistent tooling condition for maximum productivity, reduces the possibility of formulation sticking to the punch tip face and removes minor corrosion,which can also help to reduce tooling replacement costs, and saves on labour costs in terms of time spent on polishing.

Manual polishing is not recommended as it is an abrasive method and care must be taken not to deform the tip profile and embossing causing a deviation from the tablet specification. Extensive polishing of die bores can also easily alter the size and geometry of the bore leading to ejection problems and incorrect tablet size, weight and dosage. If absolutely necessary only light polishing should be undertaken manually.

Although all steps of the PharmaCare® 7-step process are important, it is arguably a combination of a good cleaning, assessment and automated polishing regime that delivers most noticeable benefit into production, reducing tablet press down time and helping to increase productivity.